Aluminum Casting Techniques: a Deep Study Products and Methods for Success

Aluminum casting methods play an essential duty in manufacturing. Various techniques exist, each suited to different applications and requirements. Sand casting is favored for bigger elements, while die casting is understood for its precision in high-volume manufacturing. Financial investment casting provides detailed designs with premium surfaces. Comprehending these differences can substantially impact task outcomes. Precision aluminum casting. Selecting the suitable technique is not constantly simple, leading to important factors to consider that have to be checked out even more.

Understanding Aluminum Casting: A Summary

Aluminum casting is a necessary manufacturing process employed across numerous markets to produce complex elements with high precision. This technique entails putting liquified aluminum right into a mold and mildew, permitting it to take the form and solidify of the wanted part. The convenience of aluminum, combined with its corrosion-resistant and lightweight homes, makes it a perfect option for applications in auto, aerospace, and customer products.

Different casting techniques exist, each suited to details demands and job ranges. Aspects such as mold materials, cooling down rates, and the complexity of the style play a substantial function in determining the most reliable approach. Furthermore, the residential or commercial properties of the aluminum alloy made use of can influence the final item's resilience, stamina, and surface area coating.

Recognizing the fundamentals of aluminum casting allows producers to enhance production procedures, minimize waste, and assurance premium outcome, which is crucial in today's open market.

Sand Casting: Applications and techniques

Among the different strategies utilized in aluminum casting, sand casting stands apart as a result of its versatility and cost-effectiveness. This approach entails creating a mold from a mixture of sand and binder, which can be shaped to suit complicated layouts. As soon as the mold is ready, liquified aluminum is put into it, enabling detailed attributes and information to be caught.

Sand casting is especially helpful for creating huge parts and low-volume production runs, making it suitable for automobile elements, machinery parts, and creative sculptures. The technique also fits a variety of aluminum alloys, boosting its adaptability in different applications. Furthermore, making use of sand as a mold product enables very easy reclamation and reuse, adding to ecologically sustainable techniques. Achieving high dimensional accuracy can present obstacles, demanding proficient workmanship and cautious control of the casting process. Overall, sand casting remains an essential technique in aluminum foundries worldwide.

Die Casting: Precision and Effectiveness

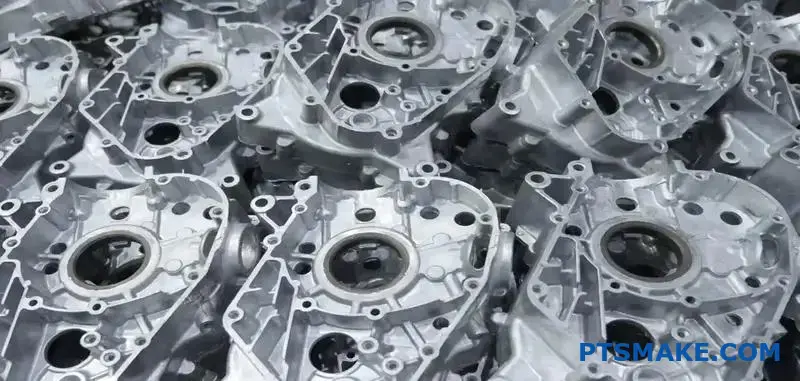

Die casting is an extremely efficient technique of creating aluminum elements with outstanding dimensional precision and surface area finish. This process involves forcing liquified aluminum into a specifically machined mold under high pressure, which enables intricate designs and minimal material waste. The rapid cooling of the alloy within the mold causes a strengthened part that frequently needs little to no extra machining.

Die casting is particularly useful for high-volume manufacturing runs, where uniformity and speed are vital. It supports the development of complex geometries, making it ideal for various applications, including vehicle, aerospace, and customer goods.

Additionally, the procedure can accommodate different aluminum alloys, improving the mechanical buildings of the finished items. With its ability to create light-weight yet long lasting parts, die casting sticks out as a preferred technique in contemporary manufacturing, providing both precision and performance in aluminum casting.

Investment Casting: Detail and Intricacy

Investment casting, additionally called lost-wax casting, is a flexible and accurate method for producing complex aluminum components. This technique is especially valued for its capability to create elaborate geometries and fine details that are commonly unattainable via various other casting approaches. The procedure starts with a wax pattern, which is covered in a ceramic shell. Once the shell solidifies, the wax is dissolved, leaving an in-depth mold and mildew for aluminum putting.

The advantages of investment casting consist of premium surface area coating and dimensional precision, decreasing the demand for comprehensive machining afterward. It is specifically useful for small to medium manufacturing runs where precision is crucial. This method accommodates various aluminum alloys, enhancing its applicability across click here industries. Aluminum Foundry. Inevitably, investment casting stands apart for its capacity to supply both aesthetic allure and practical performance in aluminum parts, making it a recommended option for engineers and developers looking for facility options

Selecting the Right Method for Your Job

How can one establish the most appropriate aluminum casting method for a certain project? The choice procedure depends upon a number of essential elements, consisting of the intricacy of the style, the wanted surface finish, and production volume demands. For intricate layouts, financial investment casting frequently confirms advantageous because of its ability to catch great details. Conversely, sand casting might be preferred for larger, much less intricate parts, offering cost-efficiency and versatility in manufacturing.

Considerations relating to resistances and mechanical properties of the final product are vital. For high-performance components, die casting may be the finest selection, as it provides exceptional dimensional accuracy and surface area quality. On top of that, comprehending the material properties and compatibility with the selected method is essential for making sure the success of the job. Ultimately, an extensive examination of these factors will lead the decision-making procedure, bring about the most efficient aluminum casting method for the certain task handy.

Regularly Asked Questions

What Is the Ecological Influence of Aluminum Casting Methods?

How Can I Enhance the Surface Complete of Cast Aluminum?

To boost the surface coating of cast aluminum, one can utilize methods such as sandblasting, polishing, and using finishes. Proper mold and mildew style and temperature control additionally significantly boost the final surface top quality of the cast item.

What Safety Safety Measures Should Be Taken Throughout Aluminum Casting?

During aluminum casting, essential safety and security precautions consist of wearing protective gear, guaranteeing appropriate air flow, using fire-resistant products, maintaining a safe distance from molten steel, and adhering to devices safety protocols to protect against crashes and injuries.

How Do I Fix Common Casting Flaws?

To repair usual casting defects, one ought to evaluate the mold and mildew for damage, evaluate the alloy make-up, check pouring temperature, change cooling rates, and guarantee correct airing vent to minimize air entrapment and improve casting top quality.

What Are the Costs Related To Various Aluminum Casting Techniques?

The expenses associated with different aluminum casting techniques vary significantly, affected by elements such as product expenditures, tools, labor, and production scale. Budget plan considerations are important for choosing the most ideal casting approach for certain projects.

Sand casting is preferred for larger parts, while die casting is recognized for its precision in high-volume manufacturing. Amongst the different techniques utilized in aluminum casting, sand casting stands out due to its versatility and cost-effectiveness. Die casting is an extremely effective approach of producing aluminum elements with extraordinary dimensional accuracy and surface area finish. Investment casting, additionally known as lost-wax casting, is a functional and exact technique for producing complicated aluminum components. Just how can one identify the most ideal aluminum casting technique for a details project?